What makes EPDM such a good commercial roof material?

Commercial roofs come in all shapes and sizes and can be made from various materials. You have many options when deciding on roofing material for your commercial building. One of the most popular materials for commercial roofs is EPDM. EPDM has proven to be a great material for use as commercial roof material for Minnesota.

But what makes EPDM such a good material for commercial roofs? This blog post will discuss the benefits of using EPDM roofing on your commercial building.

What is EPDM, and what are its benefits for commercial roofs?

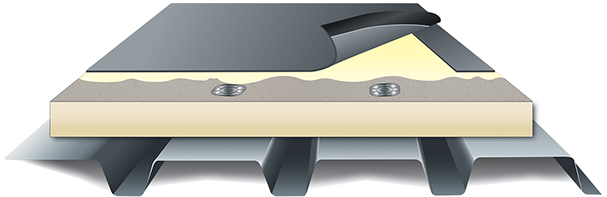

EPDM (ethylene propylene diene monomer) is a synthetic rubber used for flat roofs in commercial buildings. It comes in large sheets or rolls from manufacturers like Johns Manville, which are cut to size and then rolled out onto the roof to create a waterproof layer on top of your building.

EPDM has several advantages over other types of material: It’s affordable, durable, and easy to install.

DURABILITY – EPDM can withstand extreme weather conditions and is resistant to tears and punctures.

AFFORDABILITY – EPDM is often a more affordable option than other types of roofing materials. It is also very durable and can withstand extreme weather conditions, such as high winds and hail.

EASE OF INSTALLATION – EPDM is relatively easy to install compared to other commercial roofing materials, making it a cost-effective option with minimal downtime for your facility. EPDM typically comes in 10′ x 100′ rolls, reducing installation time compared to other materials.

How does EPDM resist weathering and UV damage over time?

EPDM resists weathering and UV damage over time by using a special coating that helps protect it from the sun’s rays. The layer acts as a UV filter, making it more durable than some other types of material that are susceptible to the sun’s rays. This coating also helps prevent the EPDM from cracking or becoming brittle in cold weather conditions.

EPDM is also resistant to chemicals and oils that can cause damage on contact with roof materials like asphalt shingles or tile roofs. EPDM has been tested against these substances for over 30 years with no signs of damage when exposed to them at room temperature over long periods.

The material is also resistant to heat, cold, and moisture; EPDM can withstand temperatures ranging from -65°F (-54°C) up through 300°F (149°C). This means it won’t crack or become brittle in extreme weather conditions.

In short, EPDM is a highly durable and weather-resistant material that can withstand a variety of extreme weather conditions, making it a perfect option for a commercial roof!

Why is EPDM a popular choice for roofing in cold climates?

EPDM is a popular choice for roofing in cold climates like we have in Minnesota. It can withstand extreme weather conditions, such as high winds, hail, snow, ice, and heavy rain. It is also resistant to tears and punctures, making it a highly durable option that can stand up to the elements.

How can you ensure that your EPDM roof lasts as long as possible?

The longevity of your EPDM roof depends on a number of factors, including where you live and how much maintenance it receives. Suppose you have an existing commercial building with an older roof that requires repair or replacement. In that case, there are some steps you can take to help extend the lifespan of your new roof by ensuring proper installation techniques are used during installation.

Preventative maintenance is always the key to extending the life of your roof and increasing its efficiency over time. Routine inspections should be conducted at least once per year (more often if there are any visible signs of wear or after a severe storm). These inspections must include a visual inspection and measurement with an infrared camera for thermal imaging purposes.

When inspecting your EPDM roof, roofing professionals will look for any signs of damage, such as tears in the membrane or cracks on its surface, which could cause water leakage into your building if left untreated.

They will also look for debris buildup along seams where two pieces meet together that could be a point of entry for water into your building.

If any of those issues are found, you should have them fixed immediately by a professional roofing contractor before they become worse over time and cause further damage to the structure underneath.

Do EPDM roofs weigh less than other roofing materials?

EPDM roofs typically weigh only 1/2 pound per square foot – significantly lighter than traditional built-up roofs, making it easier to install and less likely to damage the underlying structure. This also makes EPDM a popular choice for buildings subject to high winds or earthquakes.

TPO (thermoplastic polyolefin) roofing material is actually lighter than EPDM. Its installation consists of two sheets of thermoplastic material that are heated and pressed together. While TPO is lighter in weight than EPDM, it is not nearly as durable. TPO is not resistant to ultraviolet light like EPDM and can break down and become brittle with prolonged exposure to sunlight.

Do EPDM roofs expand and contract more or less than other commercial roofing materials?

EPDM roofs have a low thermal expansion coefficient, meaning they expand and contract very little in response to temperature changes.

This means that EPDM roofs are more stable than other commercial roofing materials and, therefore, less likely to be damaged by extreme weather conditions like high winds, heavy rain, or frequent freeze/thaw cycles.

As a result, EPDM roofs tend to require less maintenance over time, which adds to the cost-saving benefit of this material.

What are the advantages of using white or black EPDM?

EPDM is available in both black and white, with the darker color being used primarily in climates that have long winter seasons. The dark material helps absorb heat, which can assist in melting ice and snow and help reduce winter heating bills.

White or light-colored EPDM is used in warmer climates to reflect sunlight away from the building – this aids in building cooling in the hot summer months.

Is EPDM the best material for your commercial roof?

When choosing a roofing material for your commercial building, EPDM is an excellent option that offers many benefits over other materials. It is durable, weather-resistant, and has a low thermal expansion coefficient, making it less likely to be damaged by extreme weather conditions like high winds or heavy rain.

EPDM roofs also have excellent resistance to ultraviolet radiation from sunlight, which means they won’t fade or deteriorate over time as other materials can. So, if you’re looking for a long-lasting and efficient roofing material, EPDM is definitely worth considering.

The knowledgeable commercial roofing experts at Mint Roofing can help you plan your new construction or roof replacement using the materials best suited to your building and its unique characteristics.

Give us a call or send us an email today to learn more or set up a meeting to discuss your needs.

FAQs About Commercial Roofing Materials

Q: What are the key factors to consider when selecting commercial roofing materials?

Answer: When choosing commercial roofing materials, it’s crucial to consider factors such as the climate in your region, the building’s structure, budget constraints, and the expected lifespan of the roof. These factors will help you make an informed decision that meets your specific needs.

Q: What is the typical lifespan of commercial roofing materials?

Answer: The lifespan of commercial roofing materials can vary depending on the type chosen. For instance, asphalt shingle roofs usually last 20-30 years, while metal roofs can last 40-60 years or more. Regular maintenance and quality installation can extend the lifespan of any roofing material.

Q: Do commercial roofing materials come with warranties?

Answer: Yes, many commercial roofing materials come with warranties that cover defects or premature failures. The warranty duration can vary depending on the material and manufacturer. It’s essential to understand the terms and conditions of the warranty before installation.

Q: How do I know if my commercial roof needs repair or replacement?

Answer: Signs that your commercial roof may need repair or replacement include water leaks, visible damage like cracks or missing shingles, extensive wear and tear, or frequent repairs. Regular inspections by a professional roofing contractor can help identify issues before they become major problems.

Q: Is it possible to install a new commercial roof over an existing one, or does the old roof need to be removed first?

Answer: In many cases, it is possible to install a new commercial roof over an existing one, which is known as a “roof overlay” or “roof recover.” However, this option depends on the condition of the existing roof, local building codes, and the type of roofing material you plan to install. Consulting with a qualified roofing contractor can help determine if a roof overlay is a viable and cost-effective solution for your building.