What is commercial roof flashing, and do I need to know about it?

When a roofing company is in the process of building a new commercial structure, one of the most critical components to consider is flashing. Flashing refers to the materials used to seal around edges, corners, and roof penetration that protect against water entering into spaces where it doesn’t belong. In this post, we’re going to provide you with some basic information about commercial roof flashing and the role it plays in protecting your investment!

The roofing industry has many different terms and acronyms that can be confusing to those who are not familiar with the trade. The term “flashing” is no exception, as it represents a family of building materials used for sealing around penetrations through roofs – everything from vent pipes to skylights to roof-mounted appliances.

Commercial Roof Flashing: Types

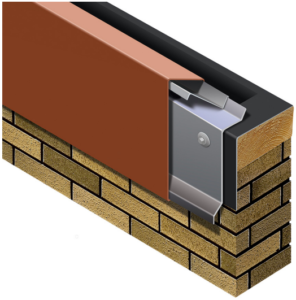

In the context of roofing, flashing refers to thin sheet metal or material used to cover an opening and prevent water from entering where it’s not supposed to go. Flashing can be made from various materials, including lead sheets, aluminum sheets, rubber membranes, and other synthetic products.

Here are some of the flashing types you might hear about when discussing your project with your commercial roofing contractor:

- Cap Flashing

- Corner Flashing

- Drip Cill Flashing

- Eaves Flashing

- Inverted Corner Flashing

- Metal Drip Edge Flashing

- Vent Pipe/Exhaust Flashing

- Vertical Expansion Joint

Commercial Roof Flashing: Materials

The most common types of commercial roof flashing include rubber, aluminum, and lead sheets, which are all used to close any openings in the rooftop area. Rubber membranes can be applied by either spraying or pouring, while sheet metal is often cut on site before being bent into shape for easy installation.

Lead sheets are one of the most malleable materials in roofing; however, they can also be challenging to work with due to their weight.

It is worth noting that some materials can prematurely degrade when they come in contact with other materials (i.e., dissimilar metals can oxidize when they meet). Your professional commercial roofing contractor will keep this in mind when installing or maintaining your roof.

Aluminum – Aluminum flashing is an excellent choice for adding detail to concrete or treating wood. It’s durable, simple to make, and relatively inexpensive. Aluminum flashing will corrode when exposed to alkaline materials like concrete or treated wood.

Copper and Lead-Coated Copper – Unlike aluminum, which can be bent and molded with relative ease, copper is more difficult to bend and shape. However, it is considerably more durable than aluminum. Copper flashing is commonly utilized in connecting solar panel pipework, wiring, and sensor connections during installation.

Galvanized Steel – Not as long-lasting or robust as other choices, but it is very inexpensive.

Lead – Lead is a popular option in the roofing business because of its tremendous flexibility and durability (masons love it for chimney flashing). There are health dangers, but using lead flashing is safe if done correctly.

Plastic and Rubber – Plastic and rubber are effective water repellants when used as flashing but are more commonly the materials used as caulking.

PVC and TPO – Roofing systems made from polyvinyl chloride (PVC) and thermoplastic polyolefin (TPO) are both popular and flashing constructed of the same material provides highly effective and long-lasting protection.

Roofing Felt – Roofing felt saturated with asphalt, which is a less durable alternative than other materials.

Commercial Roof Flashing: Use & Function

Flashing is installed by cutting it down to size and then using a sealant or caulking around the seams to prevent water from seeping into areas where it isn’t supposed to go. The best roofing companies will use the appropriate material for each application and incorporate flashing components into their installation process as a standard practice.

Why does roof flashing matter to me as a business owner?

- Flashing keeps water where it belongs.

- Flashing protects your building against leaks and interior damage.

- Correctly installed flashing protects the investment in your building and its contents.

Does commercial roof flashing ever require maintenance or replacement?

The flashing on your newer commercial roof typically doesn’t require much maintenance. However, as your roof ages, you’ll want to have the flashings inspected annually for any signs of damage or breakdown. These routine inspections will help your commercial roofing contractor catch issues early and make repairs before they become major repairs.

Commercial roof flashing is made to last, and it is rarely damaged by use or weather conditions when installed correctly. Your commercial roofing contractor will ensure that your commercial building’s rooftop is fitted with the right type of material for each application before sealing seams with sealant or caulking.

Commercial Roof Flashing: Final Thoughts

Flashing is a critical component of any commercial rooftop structure – one that protects the contents of your building from costly water damage! If your construction project requires a commercial roofing company, be sure to contact a reputable contractor who is skilled in all aspects of your project.

The commercial roofing experts at Mint Roofing can help you plan your roofing project and maintain your commercial roof. We’ll make sure that your flashing is installed correctly and maintained to get the most life from your commercial roof.

Give us a call today at 952-473-8080 or contact us online. We look forward to helping you get the most from your commercial building’s roof!

Commercial Roof Flashing FAQs

Q: What is roof flashing?

A: Roof flashing is a material used to cover openings and prevent water from entering where it’s not supposed to go.

Q: Why is proper commercial roof flashing important?

A: Proper commercial roof flashing protects your building against leaks and interior damage and helps maintain the value of your investment.

Q: Can I inspect my own commercial roof flashing for damage?

A: It is best to have a professional commercial roofing contractor inspect your flashing for damage. They are trained to spot potential issues and make repairs before they become major problems.

Q: What types of materials are used for commercial roof flashing?

A: The most common materials for commercial roof flashing include rubber, aluminum, lead sheets, and plastic/rubber caulking. The appropriate material will depend on the specific application and building needs.

Q: How often should I have my commercial roof flashing inspected?

A: It is recommended to have your commercial roof flashing inspected annually by a professional roofing contractor. However, if you suspect any damage or issues, it is best to contact a contractor for an inspection as soon as possible.